(Troy, Michigan):Engineering Technology Associates, Inc. (ETA) Dynaform software has once again demonstrated its technical prowess on the global stage, securing 2nd Place in the Scientific Benchmark Category at NUMISHEET 2025, the premier international conference dedicated to numerical simulation of sheet metal forming processes.

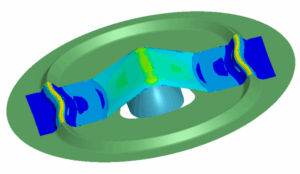

The scientific benchmark at NUMISHEET 2025 challenged participants to calibrate advanced anisotropic material constitutive models for DP800 dual-phase steel using a diverse set of experimental data along multiple orientations utilizing laser extensometer and Digital Image Correlation (DIC) system. To validate the material models, participants were tasked with simulating the MUC-Test (Material Under-Control Test), a custom-developed sheet metal forming test, to determine the punch force and major and minor strains for three different specimen geometries and rolling directions.

Dynaform’s robust simulation capabilities enabled the team, led by Dr. Subir Roy, Dr. Zhidong Han, and Dipl.-Ing. (FH) Peter Vogel, to deliver a highly accurate and computationally efficient material model and simulation results. The final assessment involved the benchmark committee comparing the major and minor strain distributions as well as force-displacement curves between simulation and experimental data, across all test cases.

“Winning second place in such a technically demanding benchmark underscores the scientific integrity and industrial reliability of Dynaform,” said Dr. Roy. “Our software continues to prove that combining cutting-edge material modeling with real-world validation can drive the accuracy and performance demanded by modern manufacturing.”

The Scientific Benchmark is regarded as one of the most challenging categories at NUMISHEET, as it closely mirrors real-world industrial challenges. It emphasizes not just numerical simulation, but calibration accuracy, model complexity, and validation through physical test data.

Dynaform’s success reflects its ongoing commitment to providing simulation tools that are both scientifically rigorous and industrially relevant, thus helping manufacturers around the world optimize sheet metal forming processes, reduce production costs, and improve component quality.

About Dynaform

Dynaform, developed by Engineering Technology Associates, Inc. (ETA), is a comprehensive simulation software solution for sheet metal forming. Known for its accuracy, speed, and user-friendly interface, Dynaform is used by OEMs, Tier 1 suppliers, and research institutions globally to streamline die development and improve product quality through advanced simulation. For more details, please visit www.eta.com or reach out to etainfo@eta.com.