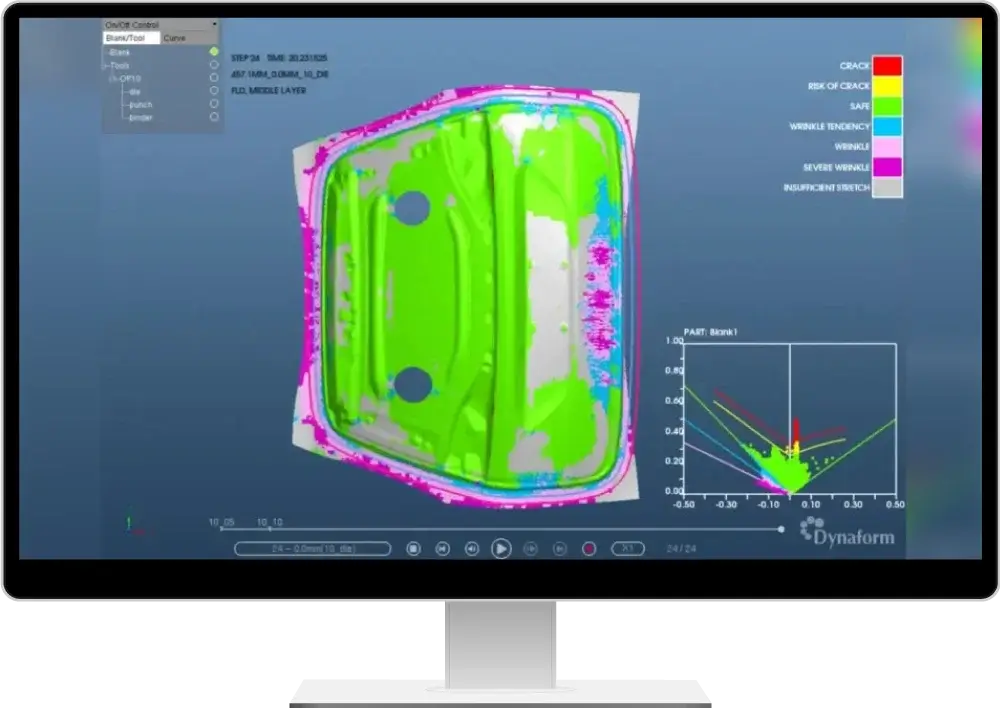

One stop solution for sheet metal forming using Stamping Simulation software

Introducing Dynaform 7.1 with advanced features

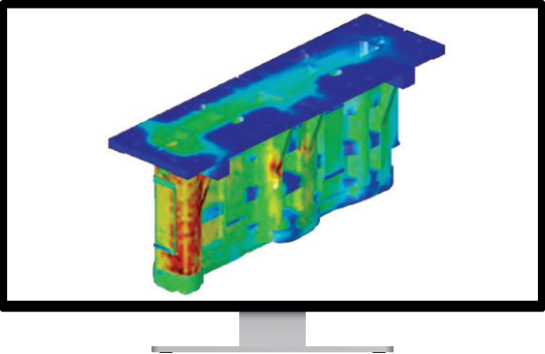

Enhancements for tool and die design

Download Dynaform 7.1 Request Demo

Achieve high quality die design and optimise process parameter without any physical tryouts using Dynaform 7.1

Major enhancements in Die Face Design (DFD) includes

- Line Die Layout

- Morph & Fill

- Auto Binder

- Part on Binder

- Butterfly Binder

- Part Trim With Offset Binder

- Inner Addendum

- Patch in Addendum

- Unfold flange (Trimline Preview)

- Smooth in feature line editor

- Flange tool design

- Improved Side-step generator

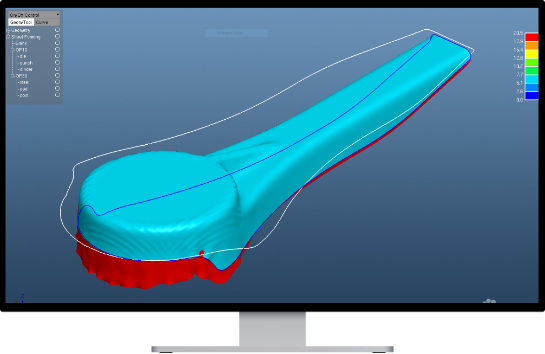

Major enhancements in Formability Simulation (FS)

- Export compensated geometry in SCP

- Sigform Solver for multistage simulation

Economical productivity

Cost-effective forming tool design using best-in-class simulation.

Speed and Efficiency

Quickly perform feasibility studies using die face design and formability evaluation.

Best-in-class Estimation

One simple interface that guides you through cost estimation, quoting, die evaluation, and formability with precision.

Highly Accurate

Accurate forming simulation results and springback correction through the LS-Dyna solver.

Your high-performing engineering teams can reach new levels of productivity

Tooling Designers

Experiment and fine-tune tooling is a way that saves time and cuts costs. Dynaform 7.1 allows you to try, evaluate and modify various scenarios before putting them into practice.

Hit Your Deadlines

Reduce Die Design Time

The Right Die, The First Time

Estimators

Dynaform7.1 gives you transparent and fast insights that allow you to quickly and accurately estimate part production costs for feasible designs, including the expected rejection rate.

Quickly Assess Project Feasibility

Generate Quotes Quicker

Reduce Project Timelines

Management

With clarity and a predictable process, you will be able to manage an efficient process and focus on building your business.

Expand Marketshare

Win More Bids

Increase Profitability

Dynaform 7.1 Introduces Die Face Design Capabilities

A quick-and-easy die face design enables a more accurate, more robust estimation process.

Die Face Design increases process reliability, efficiency, and cost reduction by bridging and streamlining the estimation and tool-building processes. Dynaform 7.1’s Die Face Design capabilities include:

Die Face Preparation

Surface edit tools aiding user in generation of binder and addendum with Dynaform 7.1.

Binder Creation

With Flat, Profile, and Manual options, users can create best-fit binder for process and die surface.

Addendum Creation

Create addendum swiftly and as intricately desired, using different addenda profile features.

Introducing Sigform – An explicit finite element code for metal sheet forming simulation.

- Accuracy and efficiency at lower prices

- Faster simulation time

- Input/output similar to LS Dyna

- Can be used without adaptive mesh for Die face design for extremely quick results fir prediction purposes

- Multistage forming simulation can be done with mesh refinement for increased accuracy but still faster than LS Dyna

Plus all the efficiency and profit driving modules that Dynaform has delivered for 30 years

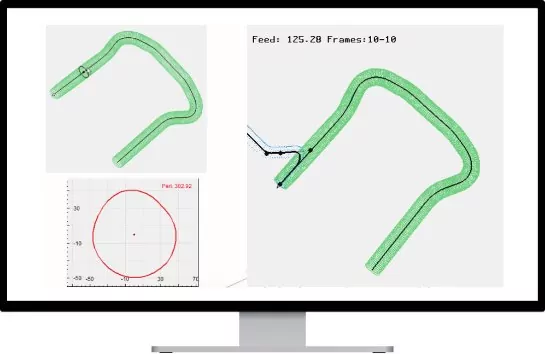

TBF / Tube Bending & Forming

Process setup and simulation for tube-bending and forming processes. Based on product geometry, TBF can automatically (or manually) setup tube-bending and hydroforming processes, generating tooling and validation processes.

Automatic Bending Process

Check the feasibility of product shape designs within a few minutes.

Bending Table Tools

The bending table supports editing, inserting, and deleting and can simulate tub feeding, rotating, and bending simultaneously.

Geometry & Automation Tools

Define tube product geometry, edit the mesh of tube products, and identify tube State/End sides automatically.

Center Line Calculation

Center lines can be calculated automatically or edited manually.

Formability Simulation

Dynaform’s forming simulation software makes it possible to uncover design flaws early in the process. Using the various modules, engineers can more-fully evaluate alternative–and unconventional–designs. Doing so helps ensure higher-quality outcomes.

Springback

Accurately predict springback during the forming process.

Springback compensation

Determine how to adjust the forming tooling or part design to compensate for springback effects.

Drawbead optimization

Optimize the design placement of drawbeads in the forming process.

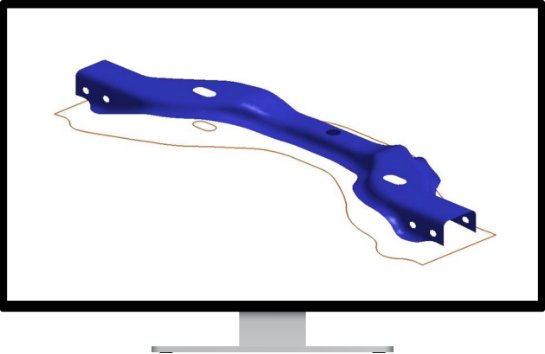

Blank & Trimeline Development

Determine a blank’s optimal shape and size before producing any physical parts. Accurately predict the deformation, thinning, and stretching that will occur during the forming process to determine the initial size and shape of the blank. Predict the final shape and contour of a part after trimming, ensuring that final part meets your specifications and quality standards.

Save Time

Run iterations and optimizations automatically

Industry Leading Accuracy

With options to change tolerance for convergency

Intuitive

Simple setup process and interface.

BSE / Blank Size Engineering

Process setup and simulation for tube-bending and forming processes. Based on product geometry, TBF can automatically (or manually) setup tube-bending and hydroforming processes, generating tooling and validation processes.

Deep Drawing

Single-part and asymmetric multi-part blanking and nesting solutions.

Line Die

Tailor-welded blanks and patchwork blanks.

Progress Die Support

Dynaform 7 helps optimize the strip concept.

Increase Efficiency

Reduce cycle time and increasing the overall productivity of the operation.

Try Dynaform 7.1 Today

Test out the quick-and-easy die face design module that enables a more accurate, more robust estimation process.