Dynaform - a complete die-system evaluation tool for tool & die businesses

Dynaform is a LS-DYNA based simulation solution empowering tool & die businesses to reduce Autoform licensing costs and run more accurate simulations.

A more accurate, lower cost simulation solution

Dynaform allows tool and die companies to reduce licensing costs while increasing the accuracy of their part simulations.

More Affordable

Dynaform costs less than other die system simulation solutions

More Accurate

Dynaform is more accurate, reducing costly production errors

Dynaform® is a simulation tool designed to improve all phases of the die development process.

Dynaform encompasses the entire die system process in one simple interface. Simulating every detail during the design stage, Dynaform ensures the highest quality formed part and best manufacturing process. The system guides the engineer through cost estimation, quoting, die evaluation and formability.

Blank Size Engineering

Unfold 3D sheet metal designs, estimate blank size, reduce scrap.

Formability Simulation

Generate formability results, prevent costly manufacturing issues.

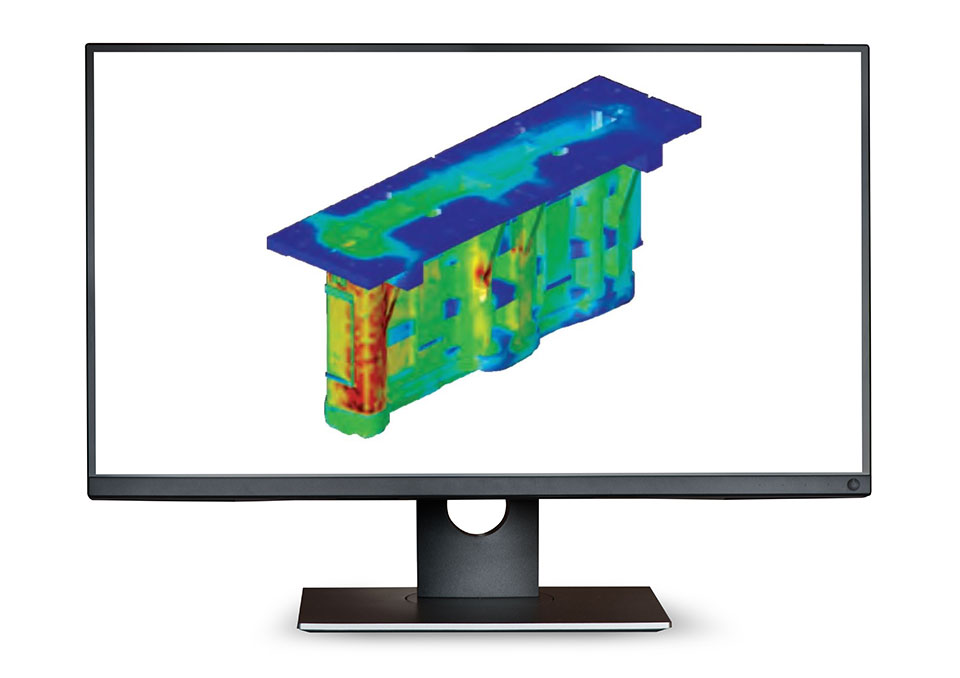

Die Evaluation

Consider formability & manufacturability early in design cycle.

Die System Analysis

Develop and design a formable part quickly and efficiently.

Blank & Trimline Dev

Near net shape simulation to accurately predict blank & trimline.

Tube Bending & Forming

Simulation of CNC bending and hydroforming of tubular products.

Die System Simulation Solution

Dynaform makes it possible to completely bypass soft tooling, reduce overall tryout time, lower costs, increase productivity and provide complete confidence in die system design. Makes possible evaluation alternative designs and materials.

Prevent Costly Errors

Go beyond just ID’ing issues. Actually improve performance & quality by reducing wrinkling, thinning & tearing.

Generate Quotes Quickly

Accurately estimate blank size and blank nesting for maximum material utilization, minimum scrap, and piece costs.

Rapid Reliable Results

Die Evaluation includes INCSolver, allowing engineers to generate reliable formability results with a short response time.

Uncover Flaws & Optimize Product Designs

Promote rapid development & validation of single-station and progressive die designs based on accurate LS-DYNA® results.

Key Dynaform modules include BSE, FS, D-Eval, and DSA. Use one or all.

Forming simulation makes it possible to uncover design flaws early in the process. Using the various modules engineers can more-fully evaluate alternative–and unconventional–designs. Doing so helps ensure higher quality outcomes.

Blank Size Engineering

Accurately estimate blank size. Minimize scrap & piece costs.

Simulate Formability

Forming Limit Diagrams indicate major strain and problem areas.

Early CAD analysis

D-Eval module analyzes CAD-based tooling during the early stages.

Got Scrap?

Use DSA mod to overcome shutdowns due to scrap removal failures.