A lot more than just unfolding

By Ming Zhang, Project Engineer

Blank Size Engineering (module: BSE) is a well-known tool in Dynaform for unfolding products into flat sheet geometry and estimating the blank material use on a coil or plate. This process normally starts with a 3-D geometry part – and just by simply defining the material and thickness, it could unfold all flanges and features to create a flat shape with an accurate outline.

Also, Blank Size Engineering has a powerful nesting function to calculate the best optimal layout for blanks on coil or plate to maximize the utilization of material. But there’s not just unfolding and nesting in BSE – we will list some functions that you might not have known about in BSE.

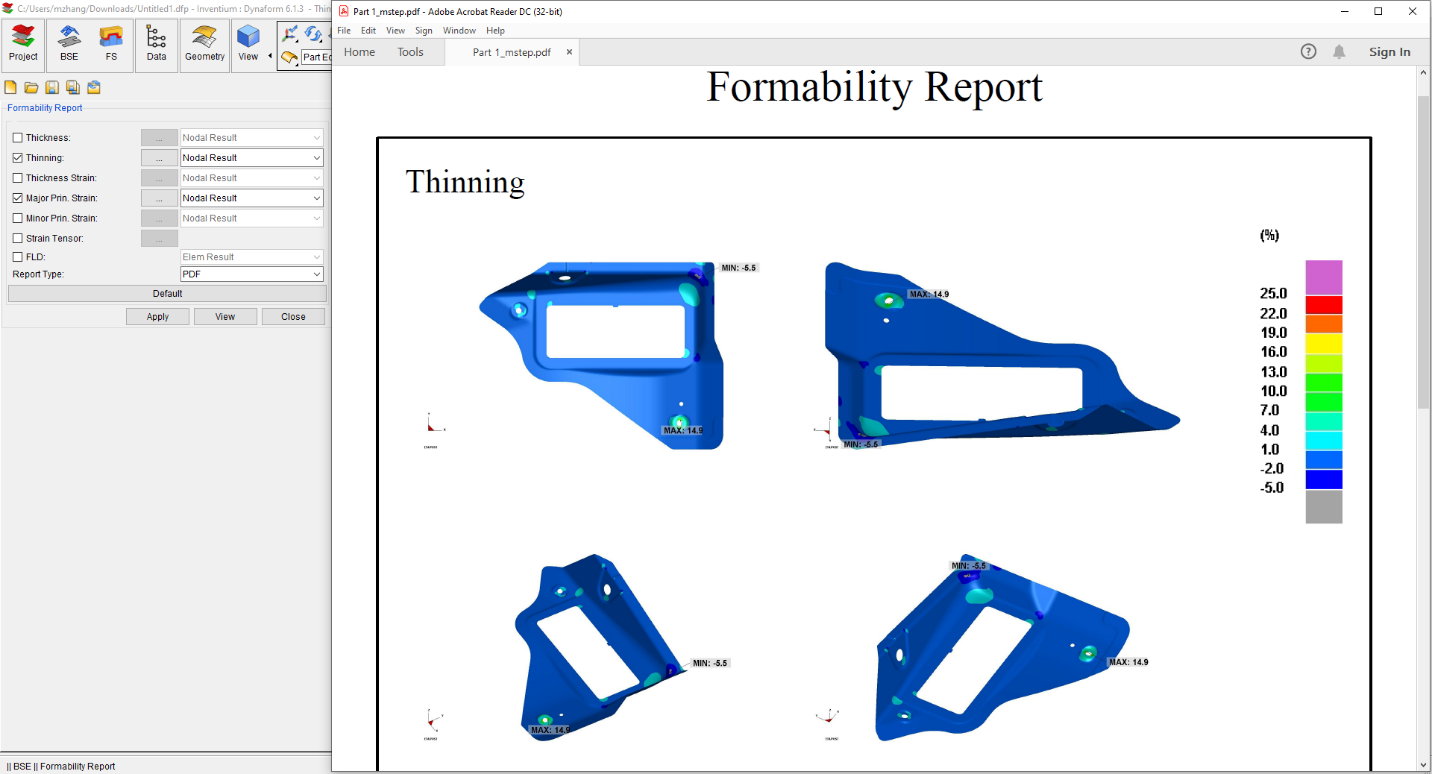

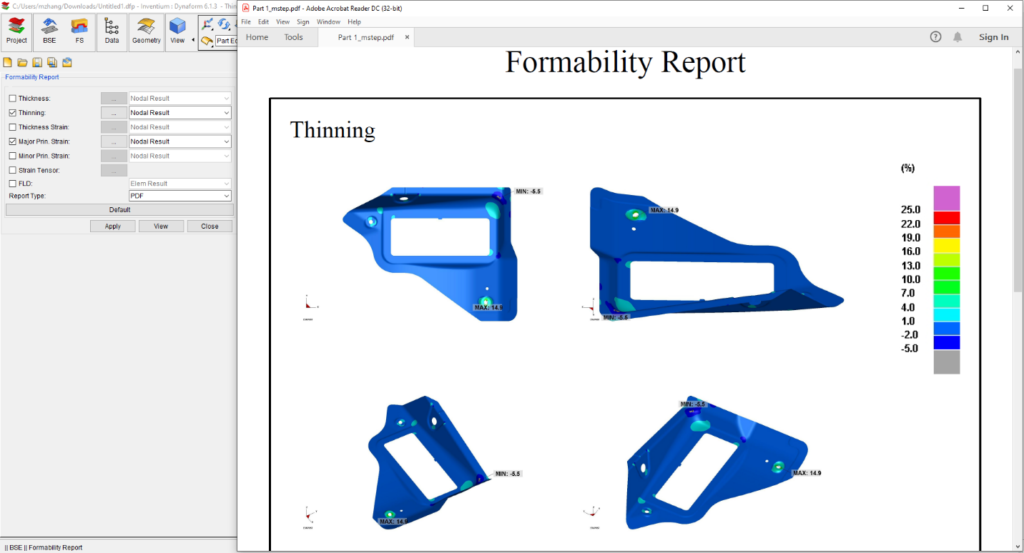

1. Feasibility analysis and report in BSE

During the unfolding process, the one-step solver not only calculates the geometry but also predicts the potential issues for forming the part. The one-step solver can quickly complete the run and it does not require any tools.

Of course, it is not as accurate as incremental solver which normally takes longer to finish the simulation. But it also could reveal major forming issues on the design, such as a risk of cracking or severe wrinkle. Items like FLD, thinning, and strain are shown in a report which can be easily generated by BSE.

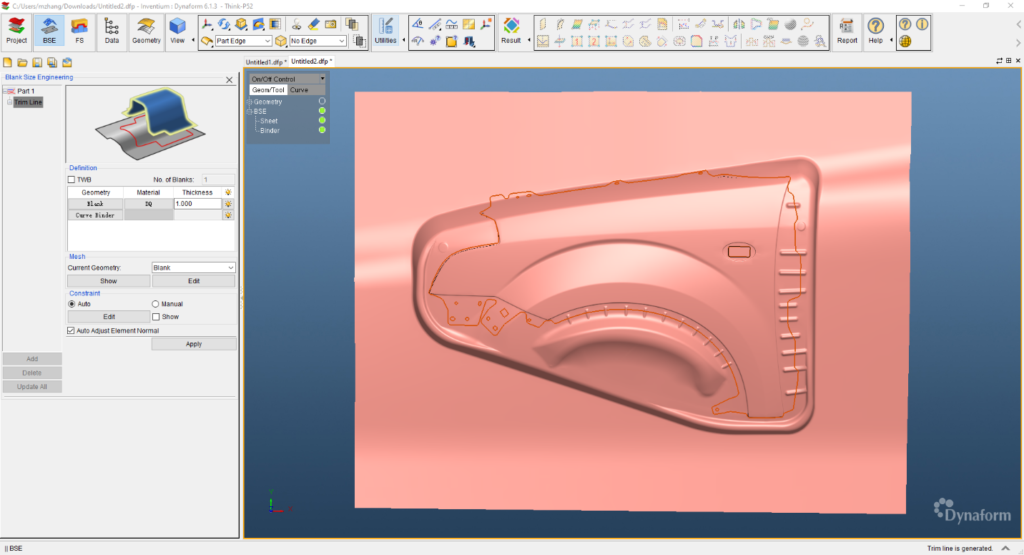

2. Trimline unfolding

It is not always easy to deal with a flange and find where exactly it will lay out on a curved binder in a multi-stage simulation. The trimline unfolding function could save huge amounts of time in finding these trimlines. This function is super simple, and is nearly “click and go” – defining the tools could not be more straightforward.

According to the feedback from OE, it is the most accurate tool by far for locating the trimline on a curved binder.

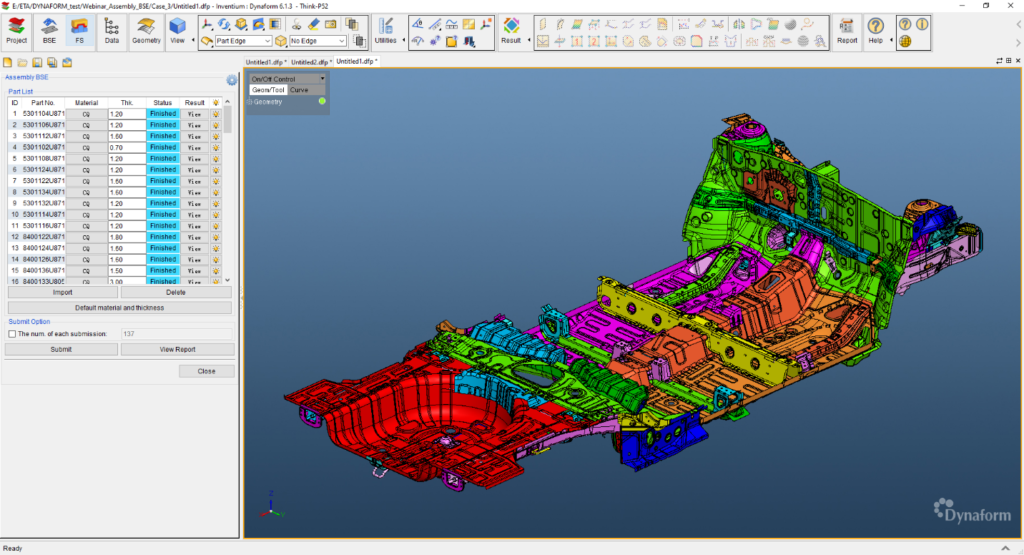

3. Assembly BSE

Blank Size Engineering is already a comprehensive tool for handling blanks – it includes many features in the advanced mode like the support of tailor weld blanks, support of patch blanks, manual and auto tipping, the combination of symmetry parts in one blank, unfold with constrain, and more.

But what about when we are working on a large assembly? It could become a time-consuming project for an assembly of a large number of parts. That’s where Assembly BSE comes in.

Assembly BSE is a new tool for running unfolding in batch mode. Material in the defining process can be read from a BOM file or manually modified. Thickness values for each part are directly read from CAD data or manually input into the database before calculation. Then with a few clicks, the blank estimating simulation will be run in queue part after part. A two-hundred-parts assembly job that usually takes two days to complete can be done in less than three hours.

With the above functions in Blank Size Engineering, it becomes a complete solution for accurately estimating blank size along with blank nesting for maximum utilization, minimum scrap, and piece costs – saving a lot of time and money for users when they need cost analysis of material.